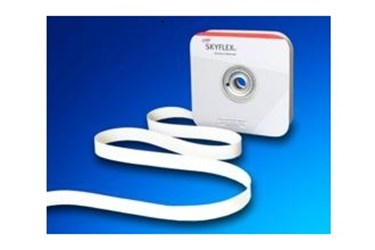

New Low-Tack Option For GORE™ SKYFLEX™ Aerospace Materials Facilitates Sealant Application

W. L. Gore & Associates has expanded its line of GORE™ SKYFLEX™ Aerospace Materials for sealing applications with the addition of low-tack adhesives to facilitate easier readjustment of sealants in difficult, complex structures during installation. Shortly after installation, the adhesive strengthens so the sealants withstand mechanical stress and maintain their protective performance for multiple open/close cycles during production and maintenance.

Newark, DE (PRWEB) - W. L. Gore & Associates has expanded its line of GORE™ SKYFLEX™ Aerospace Materials for sealing applications with the addition of low-tack adhesives to facilitate easier readjustment of sealants in difficult, complex structures during installation. Shortly after installation, the adhesive strengthens so the sealants withstand mechanical stress and maintain their protective performance for multiple open/close cycles during production and maintenance.

Unlike traditional sealants that can become brittle and crack when exposed to liquids, Gore’s new low-tack sealants provide a barrier against fluids, protecting against corrosion caused by exposure to moisture and liquids such as water, solvents, and de-icing fluids. Under compression, these lightweight, durable materials maintain consistent seals that are resistant to cut-through and abrasion, further extending their useful life.

According to Andreas Eckert, global product manager of GORE™ SKYFLEX™ Aerospace Materials for sealing applications, the new low-tack adhesive used in these sealants was engineered specifically for structures requiring thin sealants and those with complex shapes. “With decades of successful offerings in the civil and military aerospace industries, we understand the importance of reliability and aircraft availability. This new adhesive has an initial low-tack when first applied, so it is easier to adjust and reapply the sealants when working with complex surfaces. After only a few hours, the adhesive strengthens to provide the same level of durable, long-lasting protection as our other adhesives. Like all GORE™ SKYFLEX™ Aerospace Materials, this new low-tack sealant does not require curing, so aircraft availability is significantly increased.”

For more information about Gore’s full line of products for the aerospace industry, visit http://www.gore.com/aerospace or contact Petra Tillmanns at ptillman(at)wlgore(dot)com or +49/9144/601-6389.

About W. L. Gore & Associates, Inc.

Gore is a technology-driven company focused on discovery and product innovation. Well known for waterproof, breathable GORE-TEX® fabric, the company’s portfolio includes everything from high-performance fabrics and implantable medical devices to industrial manufacturing components and aerospace electronics. Headquartered in the United States, Gore posts annual sales of more than $3.2 billion and employs approximately 10,000 associates in 30 countries worldwide. In Europe, Gore started its first business operations only a few years after the Enterprise's founding in 1958. Gore now has locations— sales offices as well as production facilities--in the key European countries with around 2,000 associates dedicated to serving the markets of all of Gore's product divisions. Gore is one of a select few companies to appear on all of the U.S. “100 Best Companies to Work For” lists since the rankings debuted in 1984. For several years now, Gore has also been voted one of the best workplaces in Europe and has been ranked on top workplace lists in France, Germany, Great Britain, Italy and Sweden. Learn more at gore.com.

Source: PRWeb

View original release here: http://www.prweb.com/releases/2013/7/prweb10908166.htm