Soft Light-Curable Adhesive Offers Excellent Adhesion To COC Laminate Film

LED Optimized for Lower Energy Consumption and Reduced Costs

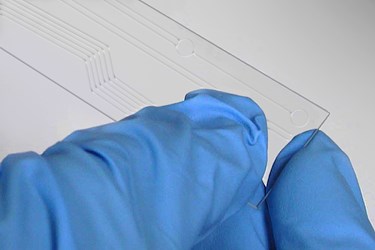

Cyclic olefin polymers/copolymers (COP/COC) have become popular choices in the point-of-care device industry because of their many advantages including high strength, hardness, low water absorption, and excellent biocompatibility. Dymax Corporation’s 1072-M MD adhesive is a new UV/broad-spectrum-cured adhesive specifically designed for bonding COC/COP film laminates and other difficult-to-bond-to polymers.

Designed to be LED optimized, 1072-M will cure in less than 3 seconds after exposure to LED or broad-spectrum UV light. Optimal cure time can be achieved by using this product in conjunction with a Dymax LED light-curing system, designed to provide users with significant advantages over conventional lamp-curing systems including cooler curing temperatures, more consistent cure results, lower intensity degradation over time, lower energy consumption, and reduced costs.

1072-M is soft and flexible with a durometer of A58. It also has a viscosity of 1,000 cP for improved wetting, making it ideally suited for interfacial bonding requirements. The product is ISO 10993-5 Cytotoxicity approved.

In addition to adhesives and coatings, Dymax also offers high-performance oligomers as well as a variety of dispensing and light-curing equipment. The company’s products are perfectly matched to work seamlessly with each other, providing design engineers with tools to dramatically improve manufacturing efficiency and reduce costs.

For more information, visit www.dymax.com.

Source: Dymax Corporation